Product

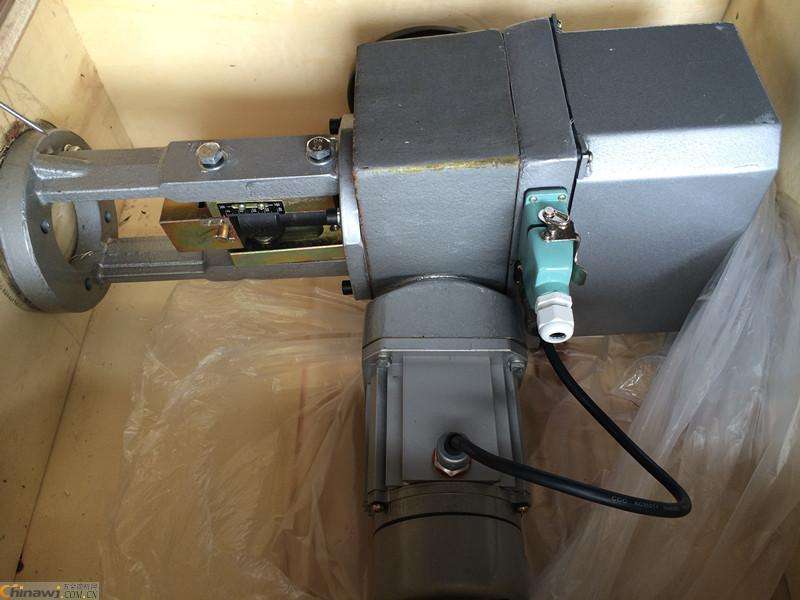

Product model: DKZ-310-M

Product Name: Angular stroke electric actuator Angular stroke electric actuator Electronic electric actuator Electronic electric actuator Angular stroke actuator

Yangzhou Bell Valve Control Co., Ltd. specializes in the production of Siemens electric actuator, Rotok electric actuator, Germany PS electric actuator, compact electric actuator, LQ series electric actuator, DKZ direct stroke electric actuator, DKJ angular stroke electric actuator, DQW partial rotary electric actuator, DZW multi-rotary electric actuator. It is widely used in power, steel plant, petroleum, metallurgy, chemical industry, building and water supply and drainage automation industry, such as electric actuators, 3810 series electronic electric actuators, electric valve controllers, electric gate valves, electric shutoff valves, electric butterfly valves, electric ball valves, electric regulating valves, check valves, solenoid valves and cut-off valves.

Introduction of DKZ Electronic Direct Travel Electric Actuator Products

DKZ type direct stroke electric actuator can not only be used with type III control unit instrument, but also with newly developed S type control unit instrument, which makes the whole control system more stable, reliable, better performance and more functions. Therefore, according to the requirements of the system for the zKz electric actuator, the user can automatically select the control unit instrument and assemble it into a control unit system.

2. Model Representation Method of DKZ Electronic Direct Travel Electric Actuator

3. Working Principle of DKZ Electronic Direct Travel Electric Actuator

When the input signal I enters 1 = 4mA. DC position feedback I inversely = 4mA. DC, the amplifier has output, the servo motor stops running, and the output axis is set at zero position in the process. When the input has an input signal (I goes into 1 > 4 mA-DC, and the polarity is opposite to the position feedback current polarity), the input signal and the position feedback current of the system itself are compared comprehensively in the magnetic potential of the preamplifier of the servo amplifier, because the polarity of the two signals is opposite. If they are not equal, there will be error magnetic potential, so that the servo amplifier has enough output power to drive the servo motor. The output axis of the actuator is operated in the direction of reducing the error magnetic potential until the position feedback signal is equal to the input signal, and then the output axis is stabilized at the stroke position corresponding to the input signal.

Because the two-phase servo motor adopts double-lever braking structure and the input signal and position feedback signal reach the normal time, the servo amplifier can send a dynamic braking signal to make the two-phase servo motor stop running immediately, so as to prove that the servo motor can stop running quickly after power failure, thus improving the electric execution. The system stability of the mechanism can limit the inertia inertia of the output shaft of the electric actuator and overcome the influence of load reaction.

IV. Installation and wiring of DKZ electronic direct-stroke electric actuator

Servo amplifier should be installed at ambient temperature of 0-50 C, relative temperature of less than 85% non-corrosive gas environment, hanging wall type, its structure can be installed vertically on the metal skeleton or column.

The actuator should be installed in the environment with ambient temperature of - 25 ~+70 C and relative humidity of less than 95% non-corrosive gas. In general, the actuator is installed on the valve body of the control valve, fastened by screw, and of course can also be installed on other regulating mechanisms. The convenience of manual operation, maintenance and disassembly should be taken into account in installation. When installing, loosening clearance of all joints must be avoided. Limiting blocks should not be loosened and disassembled.

Bell solemnly promises that all products have passed all kinds of strict quality control operations and performance tests before they leave the factory, and will be guaranteed for one year under normal service conditions from now on. However, disasters that are not human-powered, damage by external forces, and dismantlement without the consent of the company are not included in the scope of warranty.

Angular stroke electric actuator angular stroke electric actuator electronic electric actuator electronic electric actuator angular stroke actuator

Summary

DKZ direct-stroke electric actuator can be used with DDZ-III instrument, assembly instrument and TA instrument. It is powered by 220V power supply and receives a unified standard signal of 4-20mmA.DC. It transforms this into a linear displacement of the output axis corresponding to the input signal, automatically operates the control valve or other terminal mechanism to complete the automatic adjustment task, or uses an electric operator to implement manual remote control. It is widely used in the regulation system of power plant, steel, petroleum, chemical industry, light industry and other industrial sectors.

The instrument has three control modes: continuous adjustment, manual remote control and on-site manual control. The automatic control system using DKZ direct stroke electric actuator needs ZPE-2030 servo amplifier and DFD-1000 electric operator to realize manual automatic undisturbed switching of the automatic control system.